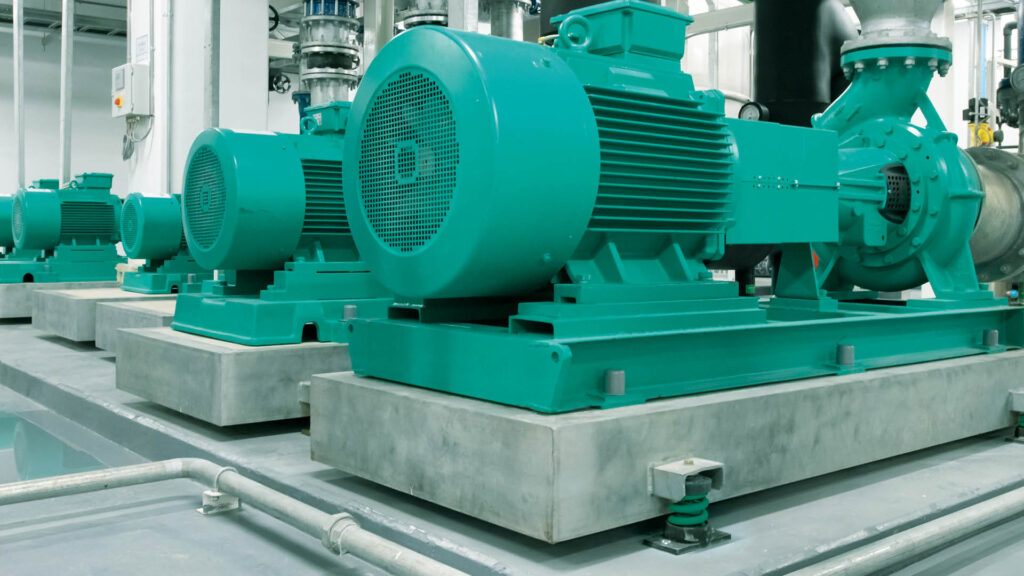

The operation of mechanical and electrical (M&E) equipment and services generates varying degrees of noise and vibration which, if left untreated, have the potential to cause damage to the equipment itself as well as disturb occupants within a building. Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations. Before we investigate and share examples of how vibration can be prevented, let’s take a look at the definition and the side effects of vibration.

What is vibration?

In simple terms, vibration is a mechanical phenomenon where

oscillations occur around an equilibrium point. These vibrations can resonate

through equipment, fixings and the building structure to create undesirable

noise and discomfort for the building occupants. In the HVAC industry, most

sound or noise is generated via rotating equipment and air and fluid movement

through ducts and pipes.

What are the most common sources of vibration?

HVAC equipment that is rigidly attached to a slab, wall, or

ceiling can transmit vibration into the supporting structure and cause highly

undesirable levels of structure-borne noise. This noise can travel far and can

even spread throughout the building. Alongside the HVAC equipment, the M&E

services such as pipework, conduits, and ductwork can also act as transmitters

of structure-borne noise if they are rigidly connected to vibrating equipment.

In an HVAC system, each vibration has the potential to travel and amplify along

miles of ducting or pipework. Not only does that make any vibration more of a

problem – it also makes it harder to track the source.

What are the effects of vibration?

Unresolved vibration can cause problems affecting both the

equipment itself, the building and its users. Recurring vibrations can cause:

Damage to the equipment

Transmitted noise

Discomfort for people

Safety issues for those near the vibrating equipment

Damage to the structure of the building

Increased maintenance requirements for the equipment

Decreased lifespan of the equipment

Malfunctioning equipment

Violation of regulatory requirements

These issues are why vibration isolation is so important.