TRACKING Delivery System

Market-leading reliability built in

Click and Collect

Buy online & collect in 30 minutes

Highly Rated on Google Business

Outstanding service as standard

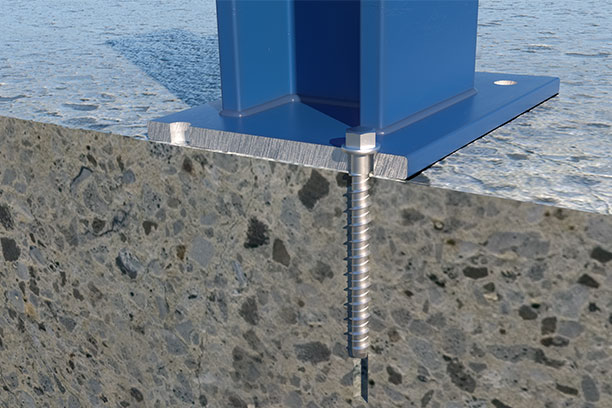

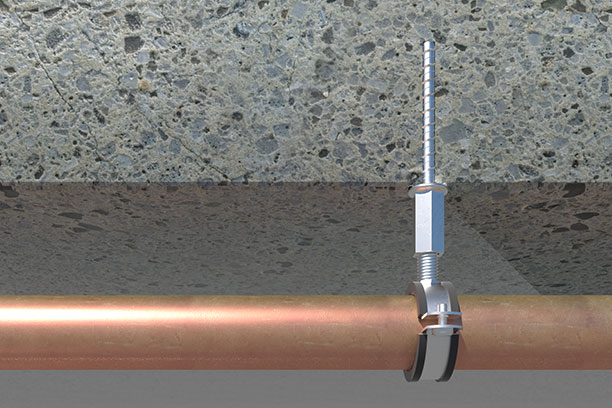

Site Visits for Your Projects

Fixings, pull tests and project advice

Trade Account

Apply for online discounts

Give us a call 01329 222 345